Four Core Elements to Implement a Sustainable Lean Management System

This is the third blog in a four-part series focused on sustaining lean transformation in healthcare organizations. To read the previous blog posts in the series, please follow the links below:

Blog #1 Establishing and Sustaining a Lean Management System

Blog #2 Maintaining Forward Movement

The critical step for any leader interested in Lean is to look beyond the tools and, instead, consider the following four core elements designed to help an organization and its leadership team to effectively implement a sustainable Lean management system.

Core Element Number One: Lean methods and systems start at the top and are rooted in values, principles, and behaviors.

Commitment to behavior change and to Lean practices begins with the chief executive. If he or she is not fully committed, the organization will quickly reach a success plateau. What’s more, when this plateau is reached, without a rooted leadership commitment, many organizations simply abandon the system entirely, saying Lean doesn’t work.

But if department heads, managers and frontline workers see commitment from those they report to, they will embrace the change and make the system work at every level of the organization.

When the president or chief executive officer makes the commitment to support system change using Lean methods, he or she is ready for the next step to look inward and identify the personal principles and behaviors that need to be adjusted in order to implement change. This step cannot be delegated and becomes a commitment that the entire leadership team must be able to see and understand. The Chief Executive sets the tone and expectation for organization-wide transformation. Only then can the leadership team agree to create a new operating system based on Lean principles and behaviors to guide the organization.

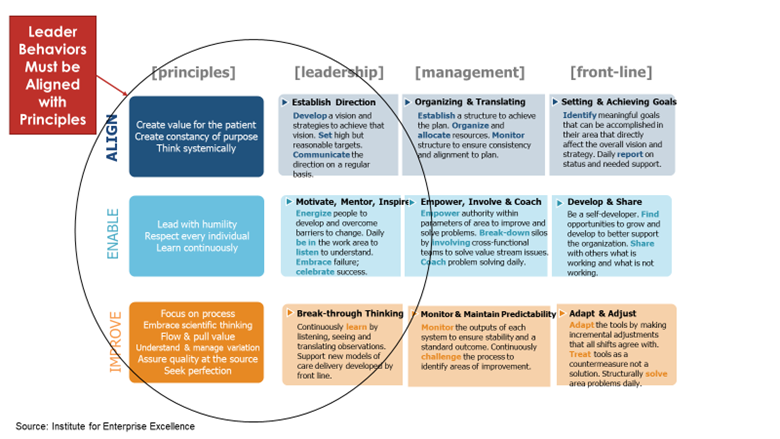

What are some of the required behaviors? The table below is rooted in the Shingo model and further defined by the Institute for Enterprise Excellence. This model highlights the behaviors and principles that leaders, managers, and front-line employees must embrace.

In addition, John Toussaint and Karl Hoover have developed a self-assessment that identifies five behavioral traits or dimensions required for leaders to build a culture of continuous improvement: willingness, humility, curiosity, perseverance, and self-discipline. These dimensions have specific reinforcing and observable behaviors to help leaders improve their ability to support the culture of improvement.

Leaders are asked to develop a plan to work on one or two behaviors that appear to have the most opportunity. Many leaders include these changes in their personal development plans and leader standard work.

Core Element Number Two: Effective Leadership, Lean principles and tools combined with a Lean management system becomes the foundation for this transformation.

An executive with a clear vision will be able to use Lean to support both strategic initiatives and daily operations. System change requires a decisive plan involving Lean methodologies and practices. This plan includes the critical steps needed to connect vision and values with the principles and behaviors that will support transformation. To connect all of this, a clear definition of how to manage becomes critical, i.e. a Lean management system. Lean, in effect, is more than a management system. It becomes a driver of the operating system for the organization itself.

As with most large-scale initiatives, organizational change demands strong, consistent leadership. Executive vision – a vision that is communicated and shared with each and every employee – is vital. And this vision must be supported with a strategy and plan that can be implemented by teams and individuals at multiple levels of the organization.

Providence Little Company of Mary (PLCOM), a 450-bed hospital in Torrance, California, quickly discovered the benefits of connecting its organization’s strategy with leadership vision. PLCOM’s CEO at the time, Mary Kingston (now an Executive for PeaceHealth), shared a common interest in implementing a Lean management system at PLCOM. Step one, and perhaps the most important, was sharing her vision with every physician and leader at the health system.

Steadily, the cascade and communication of this vision reached every employee. Through visual management, and strong communication strategies, the entire organization understood the vision, strategy and steps that needed to be taken to create PLCOM’s new Lean management system. The result? Leaders and staff worked together to create a culture that today is more adaptable and prepared to face sweeping healthcare change. Their quality measures improved as did customer satisfaction end employee engagement.

Core Element Number Three: Leaders set expectations of behavior change at every level of the organization to support and sustain the operating improvements.

At Western Sussex, Marianne Griffiths, her board of directors and leadership team created a clear vision of what’s important for the organization. As Western Sussex began its Lean journey, leadership focused on a patient-first program to transform the organization. Each employee was asked to make continuous improvements to benefit patients.

Using a breakthrough/Kaizen approach they began their journey. As they moved forward, they added a Lean management system they referred to as their “Patient First Improvement System.”

The Patient First Improvement System serves as a framework for service development at the hospital with a focus on redesigning systems to remove waste and reduce errors, and to standardize practices so every patient gets great care and service.

The entire staff at Western Sussex have become an army of problem solvers with the permission and skills needed to make change that improves service for patients. In April 2016, the Care Quality Commission (CQC), the independent regulator of health and social care in England, gave Western Sussex an Outstanding rating – one of only three acute trusts in Great Britain to receive the highest possible grade. In 2019, they were the first hospital in the U.K. to achieve an outstanding CQC rating in all categories.

Core Element Number Four: Educate the board of directors to generate long-term support for organizational change.

The first three core elements stress the importance of developing leaders and teams who will support the organization’s vision, strategy and need for organizational change. But it’s equally important to take this a step further – to the full board of directors, including the non-executive members.

In order to create long-term board support of a major initiative such as adopting a Lean management system designed to transform the organization, the CEO must educate each board member about his or her role.

The board of St. Mary’s General Hospital in Kitchener, Ontario, improved its governance practices using the plan-do-study-act cycle – a tool for accelerating improvement.

The board began its Lean journey by aligning the organization under a clear and aspirational vision: “to be the safest and most effective hospital in Canada, characterized by innovation, compassion and respect.” The vision was then supported by the operational goals of eliminating preventable harm; improving the patient experience; developing, supporting and sustaining a culture of problem solvers; and reducing the cost of quality healthcare.

The result was a board that believed in the organization’s vision and strategic direction; and a hospital president who trusted that board members would support his decision making at the operational level.

In the next (and final) blog of this series, I will share about results I have seen of organizations taking these elements and effectively applying them.

Related Items

Leave a Reply